inquiry@deltasales.co.in

+91 9545550876

inquiry@deltasales.co.in

+91 9545550876

Hydraulic Cylinder Manufacturers in Pune,India|High Performance Hydraulic Cylinder Manufacturers in Pune|Hydraulic Cylinder Manufacturers in Pune India

Top Hydraulic Cylinder Manufacturers in Pune, India|Delta Hydraulics Pune, MH, India|India's leading Hydraulic Cylinder Manufacturers

Hydraulic Cylinder Manufacturers in Pune, India | Hydraulic Cylinder Manufacturers in Pune | Hydraulic Cylinder in Pune| Find Hydraulic Cylinder in Pune India. As we are leading Hydraulic Cylinder Manufacturers in Pune Hydraulic Cylinder Suppliers in Pune from India we are offering quality material Hydraulic Cylinders in Pune India.Get Hydraulic Cylinder from Pune Get Quote Now.

Related Searches of Manufacturers of Hydraulic Cylinder:Hydraulic Cylinder, Trunnion Mountings Hydraulic Cylinders, Pivot Mounting Hydraulic Cylinder, Hydraulic Cylinder Manufacturers in Pune, Hydraulic Cylinder Manufacturers, Hydraulic Cylinder Manufacturers in India, Hydraulic Cylinders in Pune.

Get Hydraulic Cylinder from leading Hydraulic Cylinder Manufacturers in Pune. We are topmost Hydraulic Cylinder Manufacturers in Pune from India and Hydraulic Cylinder Suppliers in Pune. Also offer Trunnion Mountings Cylinders, Flange & Side Lugs Mounting, Pivot Mounting and our set up is situated in Pune, Maharashtra, India.

Our high performance Hydraulic Cylinder are used in applications like Robotic Automation, Aircraft Landing Gear, Hydro electric Dam Gates etc.Delta Hydraulics is a former hydraulic cylinder manufactures suppliers, exporters in Pune, Chakan. We are providing the best quality hydraulic cylinders, which are made with pure quality cast iron from the outside and heavy-duty steel from the inside for smooth momentum.

These are the mechanical devices that use pressurized hydraulic fluid to generate force and linear motion. They provide the necessary force needed to lift, push and pull heavy loads. In multiple industries, such as construction equipment, manufacturing machinery and vehicles such as trucks, tractors and excavators, our hydraulic cylinders are highly used.

Our Different Types of Hydraulic Cylinders:

As a former hydraulic cylinder manufactures and suppliers in Pune and Chakan, we offer our major and commonly used types, which are built with advanced qualities of mechanisms and helpful in multiple applications. Here we have listed down some types, such as:

- Trunnion Mountings Cylinders: In heavy and complex industries such as construction and industrial machines, our Trunnion mounting cylinders are highly used due to their strong structure and smooth momentum. It consists of a hydraulic cylinder using Trunnion pins, which allows for rotation around a fixed axis. The whole cylinder body is typically mounted to the Trunnion pins, which have a fixed structure. Due to the fluid dynamics in these cylinders, it gives linear motion for operating and better force of distribution. We have added smart sensors and sealing technologies to these cylinders for more accurate work without any failure.

- Flange & Side Lugs Mounting: In these types of hydraulic cylinders, the flange and side lugs are connected to the cylinder's body and allow direct attachment to a mounting surface. The hydraulic cylinder extends its piston rod and is mounted towards the structure for stable operation. This whole mounting style of these cylinders helps to improve accuracy, vibration and momentum. The advanced quality of fluid dynamics is used in this hydraulics for moving the piston in a uniform direction, and the modular design gives effective and easy replacement of cylinder components without replacing the entire unit. These are usually applied in the manufacturing and automotive industries.

- Pivot Mounting: This hydraulic cylinder has fixed pivot mounting and uses a pin connection. The specialty of these cylinders is that they use angular motion instead of linear motion. This feature helps for usingthis cylinder in multiple applications, such as agricultural equipment like loaders, tractors and implements. Due to the latest advancement, we have included adaptive control systems in these cylinders, which automatically adjust hydraulic pressure and flow based on load conditions. Also,the self-lubricating functions help reduce friction while working on heavy tasks and improve the lifespan of the cylinder.

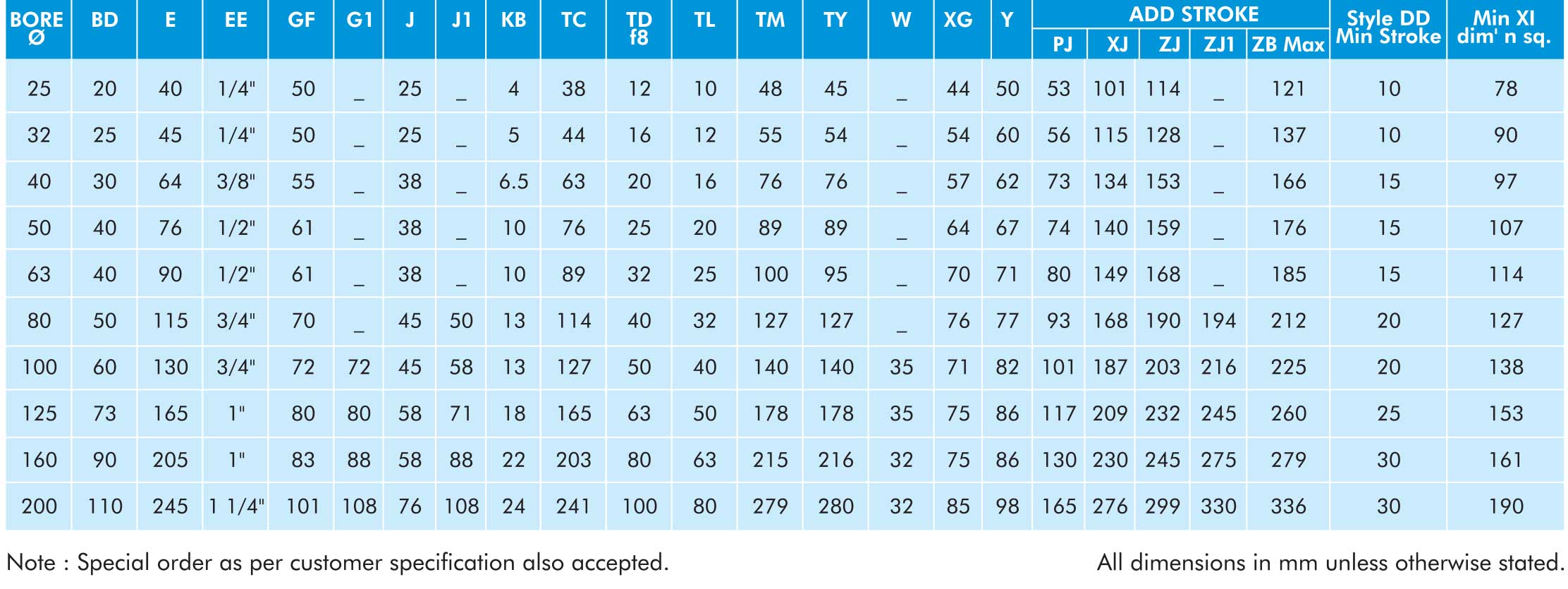

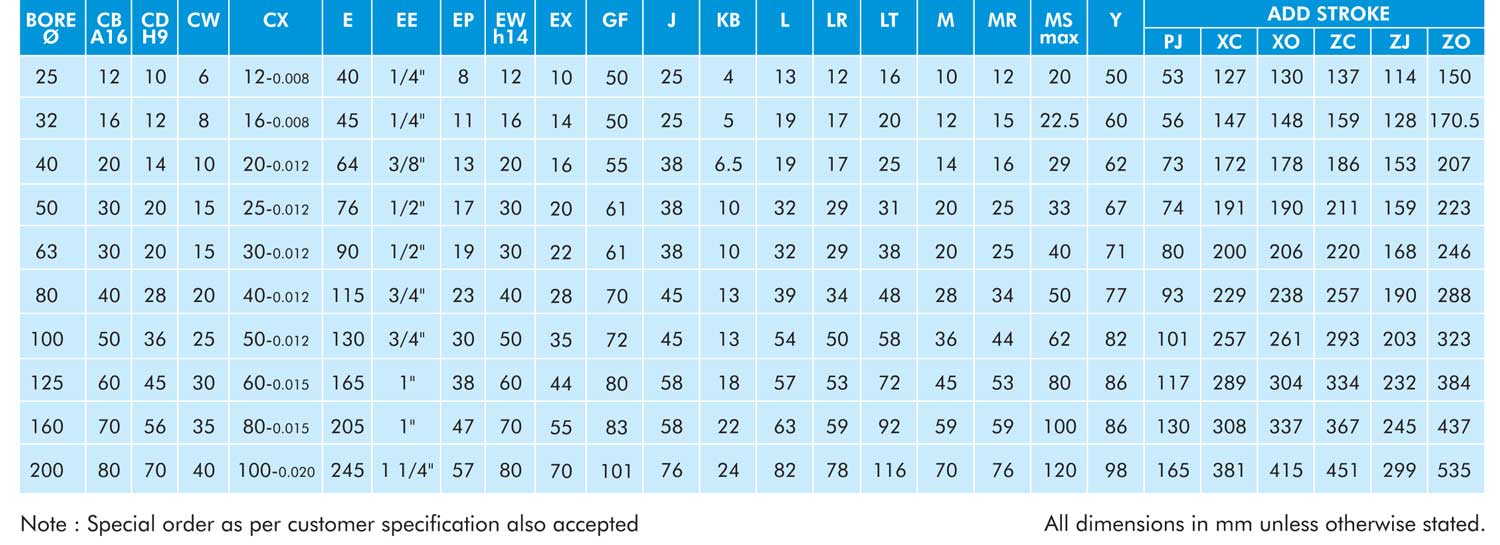

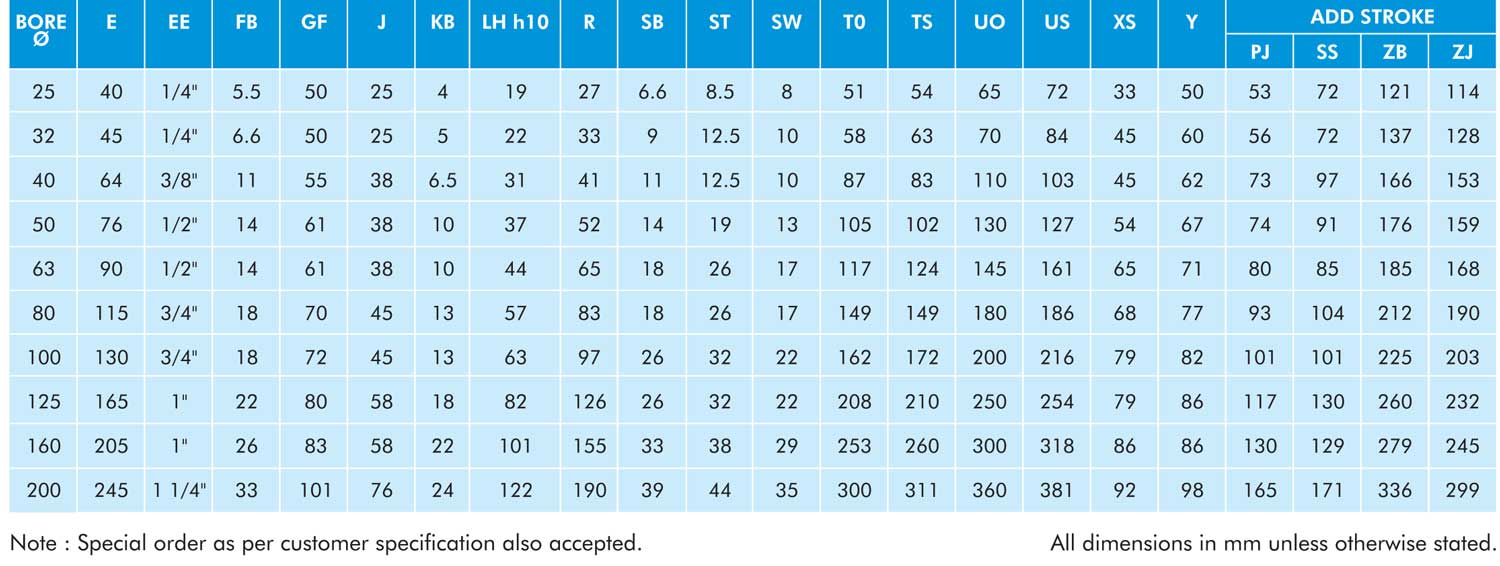

Technical Specifications :

We have included below an advanced technical sheet of our hydraulic cylinder types and it will guide you for increasing your performance in every applied application:

| Technical-Specification | Trunnion-Mountings-Cylinders | Flange-& Side-Lugs-Mounting | Pivot-Mounting |

|---|---|---|---|

| Mounting Style | Trunnion at either front, rear, or intermediate position | Flange at front, rear, or side lugs attached to cylinder body | Pivoting clevis, spherical bearings, or pivot brackets at ends |

| Material | High-strength alloy steel or cast iron | Alloy steel, stainless steel options available | Cast iron, steel with protective coatings |

| Operating Pressure Range (bar) | 70-700 bar | 70-350 bar typically | 50-500 bar |

| Bore Size (mm) | 25mm to 500mm | 25mm to 400mm | 30mm to 450mm |

| Stroke Length (mm) | Up to 6000mm | 100mm to 3000mm | 100mm to 4000mm |

| Mounting Flexibility | High flexibility due to trunnion position options | Medium flexibility, mounting fixed at flange points | High flexibility due to ability to pivot in one or more planes |

| End Configurations | Eye-end, clevis, threaded rod ends | Threaded ends, eye mounts | Eye mounts, clevis mounts, spherical bearings |

| Cylinder Rod Diameter (mm) | High-performance hydraulic seals for high pressure | Standard hydraulic seals with optional high-temp seals | Wear-resistant seals for continuous movement |

| Load Capacity (kN) | 5 kN to 500 kN | 10 kN to 400 kN | 8 kN to 450 kN |

| Operating Temperature Range (°C) | -20°C to 150°C | -10°C to 120°C | -30°C to 100°C |

| Rod Coating | Hard chrome-plated, nickel, or ceramic coatings for wear resistance | Chrome plating, optional ceramic or zinc coating | Hard chrome-plated, ceramic coated for wear resistance |

Unique features and benefits of using our new technological hydraulic cylinders:

Being a best hydraulic cylinders suppliers and exporters in Pune and Chakan, we have installed new technological features in our hydraulic cylinders for increasing your performance. Here we have given some important features:

- Integrated Position Sensing & Feedback Systems (Smart Cylinders): We have included new technological smart feedback systems with integrated position sensors in our hydraulic cylinders. Due to these sensors, they give liner displacement transducers and provide real-time feedback on piston position and movement. This advanced system is more useful for providing accurate and exact movement of pistons and is highly used in robotics, automated manufacturing, CNC machinery, and aerospace systems.

- Energy Recuperation Systems: Our hydraulic cylinders and their all types are now integrated with the new technology, such as energy recuperation systems. This system helps store energy from the fluid and reuses it when the cylinder retracts or detracts. It reduces the overall energy consumption, improves efficiency and can be applied to electrical construction equipment, advanced industrial presses and sustainable energy systems.

- Adaptive Load Sensing and Variable Pressure Control: Each hydraulic cylinder is connected with adaptive load sensing technology. This technology automatically senses the load and adjusts the pressure dynamically based on the load and working conditions. This feature is more helpful for high-demand mobile machines such as excavators and agricultural machinery.

- Advanced Sealing Technology with Self-Lubricating Systems: Our new self-lubricating seals and advanced sealing materials such as PTEE and polyurethane are used in our hydraulic cylinders to reduce unwanted friction. This function improves the overall durability and performance and gives smooth functioning of the cylinders. In multiple types of advanced applications, such as oil rigs, deep-sea equipment and high-altitude aerospace systems, this technology in our hydraulic cylinders is more helpful.

Applications of our Hydraulic Cylinders:

As a former hydraulic cylinder manufacturers and suppliers in Pune and Chakan, our all types of hydraulic cylinders are highly used in multiple advanced types of applications such as:

- Robotic Automation: This hydraulic cylinder provides accurate motion control in heavy-duty industrial robots for lifting and positioning tasks.

- Aircraft Landing Gear: Our hydraulic cylinders power landing gear extension and retraction systems in aircraft, ensuring smooth and reliable operations.

- Offshore Drilling Equipment: These hydraulic cylinders support lifting and positioning of massive components on oil rigs, even under extreme underwater conditions.

- Hydraulic Presses: Used in metal forming and forging presses for high-pressure, heavy-duty material processing.

- Hydroelectric Dam Gates: These hydraulic cylinders control large sluice gates in dams to regulate water flow and power generation.

- Mining Excavators: Our hydraulic cylinders enable the movement of boom arms and shovels for efficient excavation in mining operations.

Being one of the best hydraulic cylinder manufacturers, suppliers and exporters in Pune and Chakan, we as Delta Hydraulics are dedicated for simplifying critical tasks in multiple types of large industries through our new technological hydraulic cylinders. These technologies increase the productivity and performance in every application and reduce in labor cost. Contact us today for information!

Related Searches: Hydraulic Cylinder in Pune, Hydraulic Cylinder in Chakan, Hydraulic Cylinder Manufacturers in Pune. Hydraulic Cylinder Suppliers in Pune, Hydraulic Cylinder Exporters in Pune, Hydraulic Cylinder Manufacturers in Chakan. Hydraulic Cylinder Suppliers in Chakan, Hydraulic Cylinder Exporters in Chakan

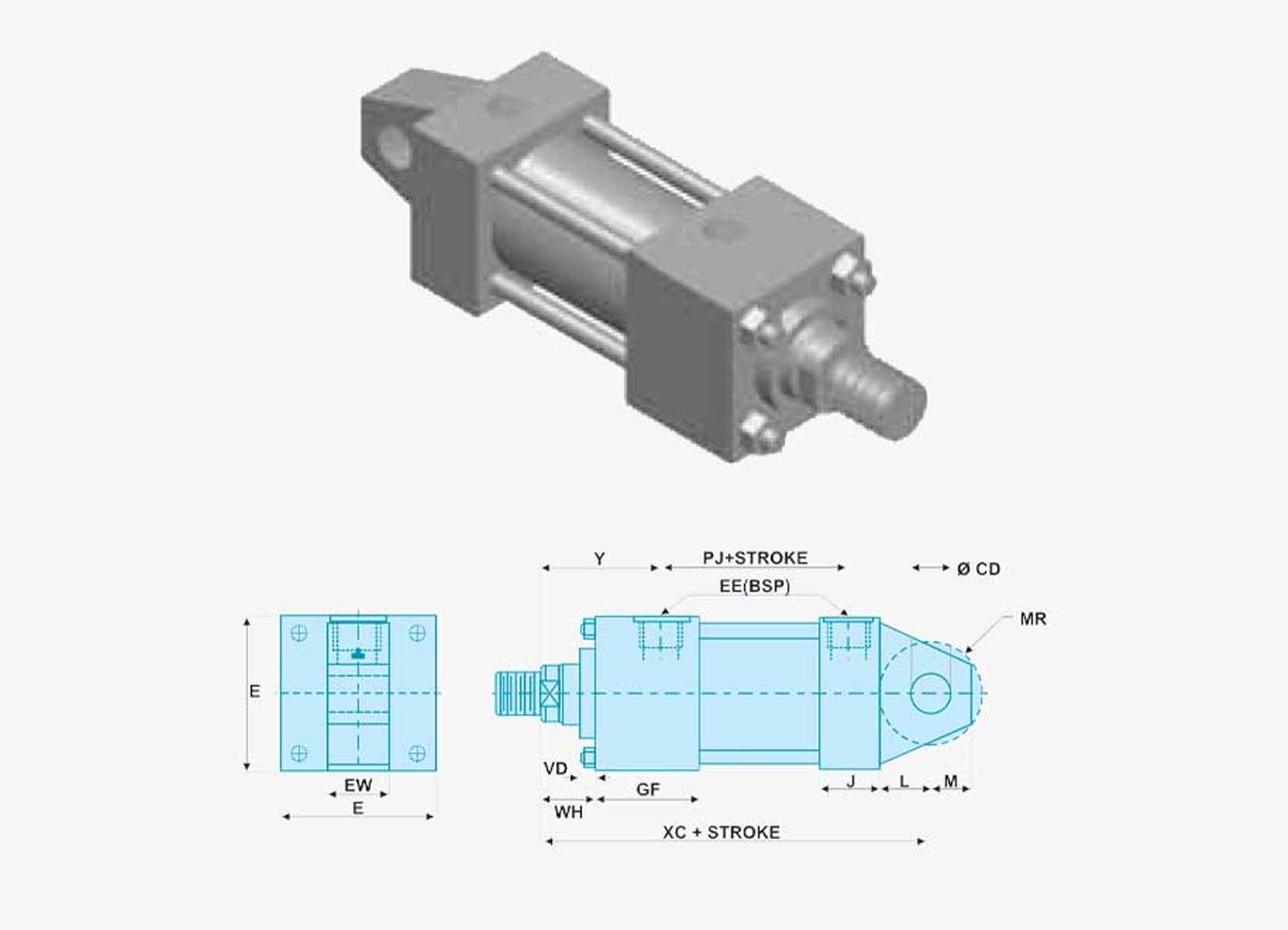

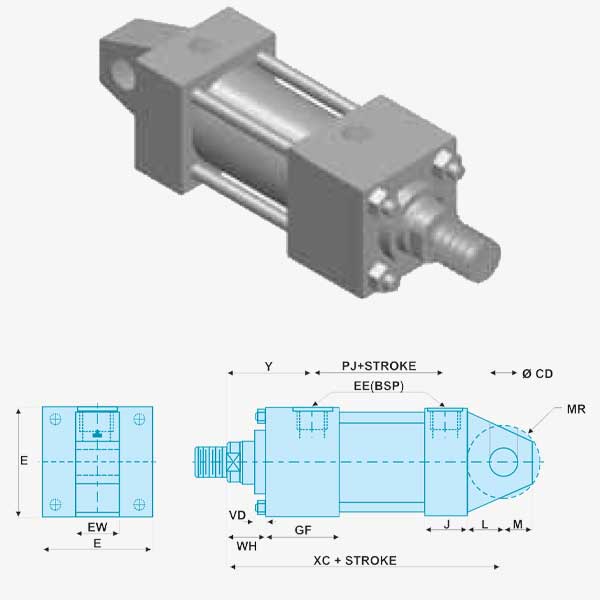

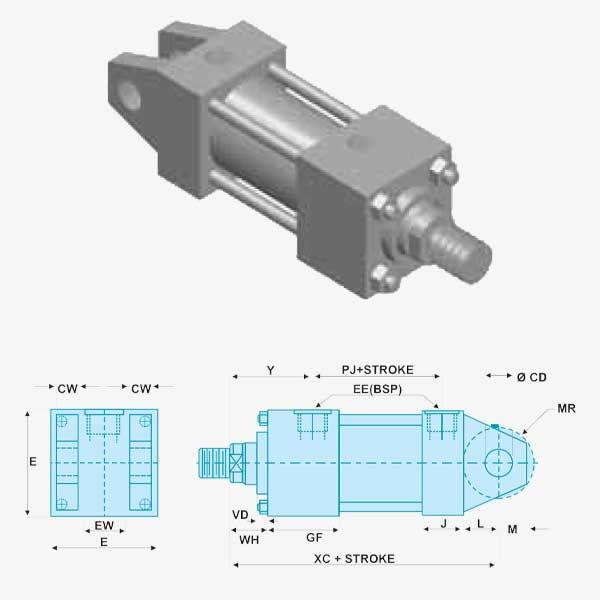

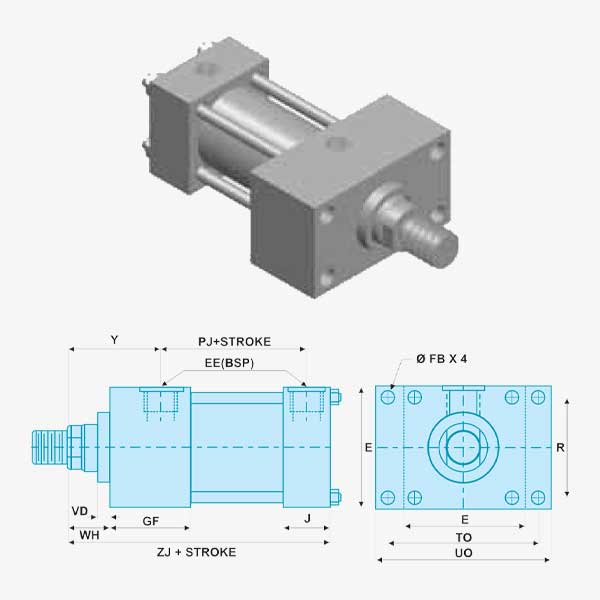

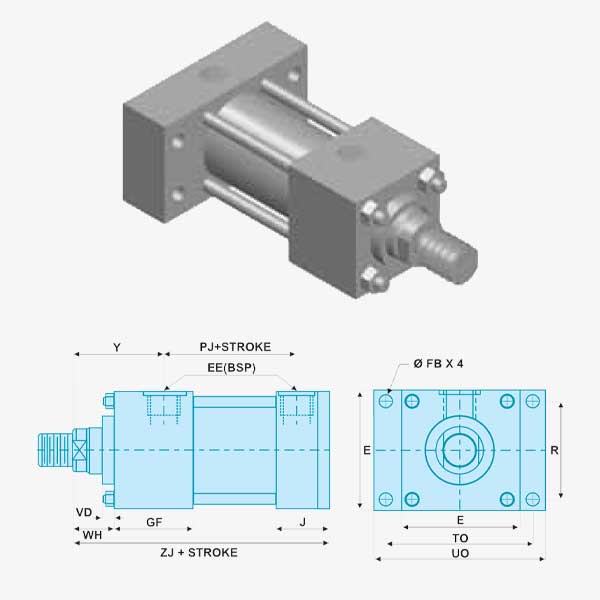

Series DT up to 210 bar (Trunnion Mountings)

MT1-Head Trunnion Mounting

MT2-Cap Trunnion Mounting

MT4-Intermediate Fixed Trunnion Mounting

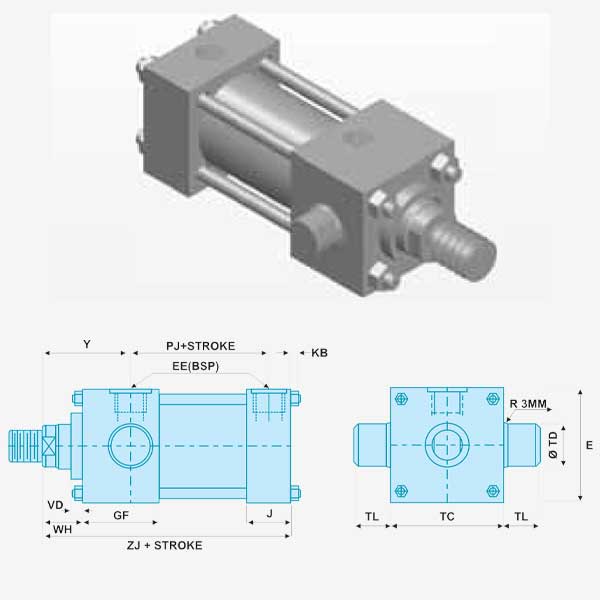

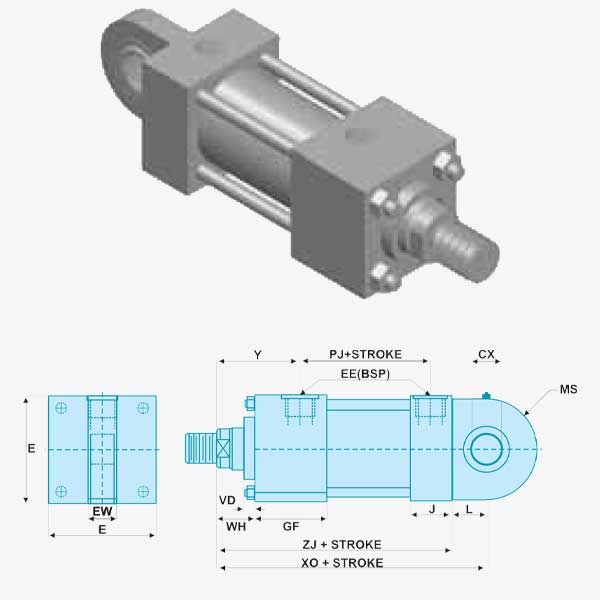

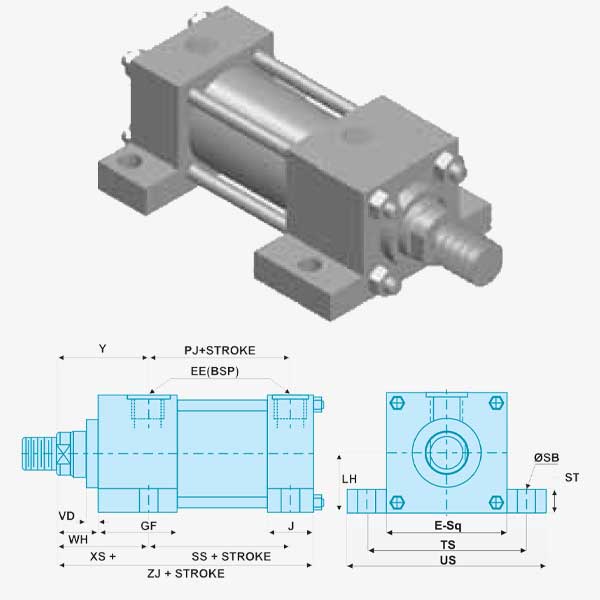

Series DT up to 210 bar (Pivot Mounting)

MP3-Cap Mounting Fixed Eye

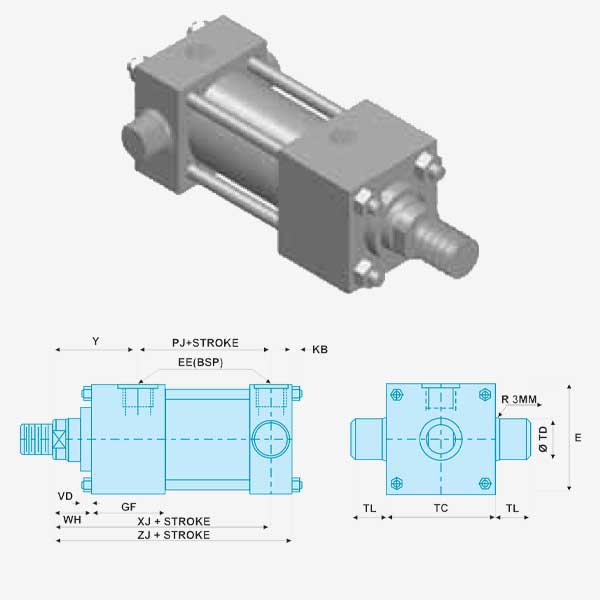

MP1-Cap Mounting Fixed Clevis

MP5-Cap Mounting Fixed Eye

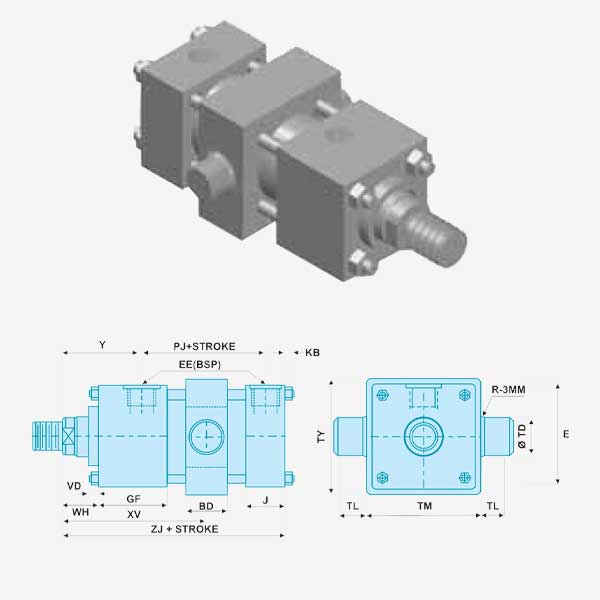

Series DT up to 210 bar (Flange & Side Lugs Mounting)

ME5-Head Rectangular Flange

MP1-Cap Mounting Fixed Clevis

MP5-Cap Mounting Fixed Eye

Frequently Asked Questions (FAQs)

Cylinders, Particularly large ones, should be stored closed in a vertical position with the rod end down.

The oil line cleared

Around 15 to 20 years

While the fluid does not freeze, the gel becomes thicker and thicker the colder it gets

Delta Hydraulics team is here to answer your questions.

Ask us anything...!!!

Hii... How can I help you?

2024 Delta Hydraulics All Rights Reserved